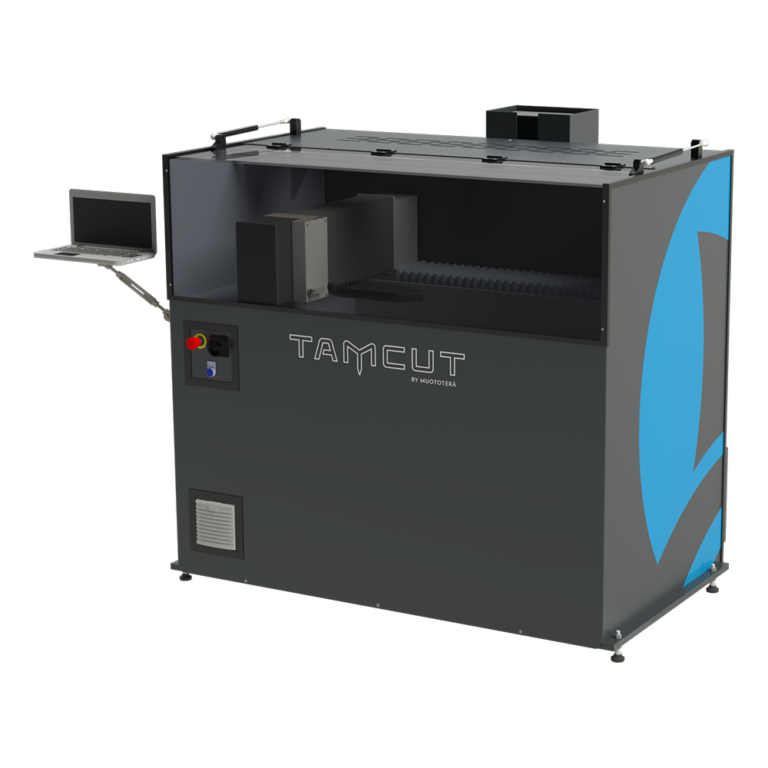

Small in Size. Versatile in Action. Simple to Use.

Meet TamCut – Ushering in a new era of waterjet cutting technology.

TamCut is brand from Muototerä – The Nordic Waterjet Company. Waterjet Cutting learnings and doings since 1987, company established in 1953.

TamCut - A New Waterjet Cutting Innovation

TamCut is a compact waterjet cutting machine capable of cutting almost any material. Common cutting materials include aluminum, steel, carbon fiber, plywood, stone, rubber, and composites. Due to its versatility, it’s suitable for nearly all industrial sectors as well as educational institutions.

Versatilely suited for various industrial sectors

The versatility of the TamCut waterjet cutter makes it a beneficial tool for the cutting needs of various industries. In the industrial sector, the waterjet cutter offers a cost-effective method to precisely and quickly cut different materials, while in educational institutions, it provides students with a hands-on tool for material handling and research.

Due to its compact size, the device is also easily portable and adaptable for various projects. Moreover, the precision and repeatability of TamCut make it an excellent choice for small-scale manufacturing projects and prototype cutting.

Versatility

Cut almost any material

Economical

Low purchasing and maintenance costs

Quick-start

Fast commissioning and start of production

Compact

Due to its size, the machine is easy to place

Safe

Safe to use due to the closed structure

Pristine

No material changes due to heat affect zone

User-friendly

Waterjet cutting made really easy

Sutainability

No hazardous waste, no toxic fumes

Technical specifications

tamcut 400

Cutting area

400mm x 450mm

Dimensions (W x D x H)

1000mm x 1150mm x 1400mm

Weight when filled with water

650 kg

tamcut 1000

Cutting area

1050mm x 450mm

Dimensions (W x D x H)

1700mm x 1150mm x 1400mm

Weight when filled with water

750 kg

-

Water supply 4-6 bar, 10L / min

-

Power supply 16A/400V

-

High pressure pump 5,5 kW / 7,5 hv

-

Max. pressure 2000bar

-

Position accuracy +/- 0,08 mm (20° C)

-

Repeatability 0,05 mm

-

Speed 4000 mm/min

-

Water orifice 0,25 mm

-

Focusing tube max. 0,90 mm

-

Flow rate 1,6 l / min

-

Abrasive container 10 l / approx. 1h cutting

Simplifying Waterjet Cutting

The machine includes all necessary software and an extensive material database with ready cutting parameters. All you need do is select the material, thickness, and the desired cut quality in a scale of 1 to 5. TamCut does the rest!

Commissioning the machine is quick and easy. Cutting can be started the same day the new TamCut waterjet cutting machine arrives.

Included in the Package

- TamCut waterjet cutter

- 2000 bar direct-drive high-pressure pump

- Cutting head

- Control computer

- Software: TamCut user interface, Material library, Path drawing program for cutting

- 1-year warranty

Cut most materials into various shapes

TamCut is suitable for most of the industries, including applications in metal, glass, plastic, composite, wood, rubber, and stone industries.

MAterial

MAX THICKNESS

Rubber

30 mm

Marble

25 mm

Aluminium

20 mm

Glass

20 mm

Plastics

20 mm

Wood

20 mm

Copper

15 mm

Stainless steel

12 mm

Titanium

12 mm

TamCut explained

TamCut is a self-contained cutting system suited for all industries. Despite its small footprint it’s an industrial grade waterjet cutting machine that cuts practically all materials.

01

Water Source and Pump

At the heart of any waterjet machine is its pump. TamCut uses a direct drive pump to pressurize water to ultra-high levels, typically slightly under 2000 bar. This is essential for cutting materials with precision. In most cases normal tap water is suitable for cutting.

02

Abrasive Materials

For tougher materials, abrasives like garnet will be used with water for maximum cutting power. While the TamCut is efficient with just water for softer materials, the addition of abrasives can help with harder materials. The machine has an abrasive feed system that mixes the abrasive with the pressurized water.

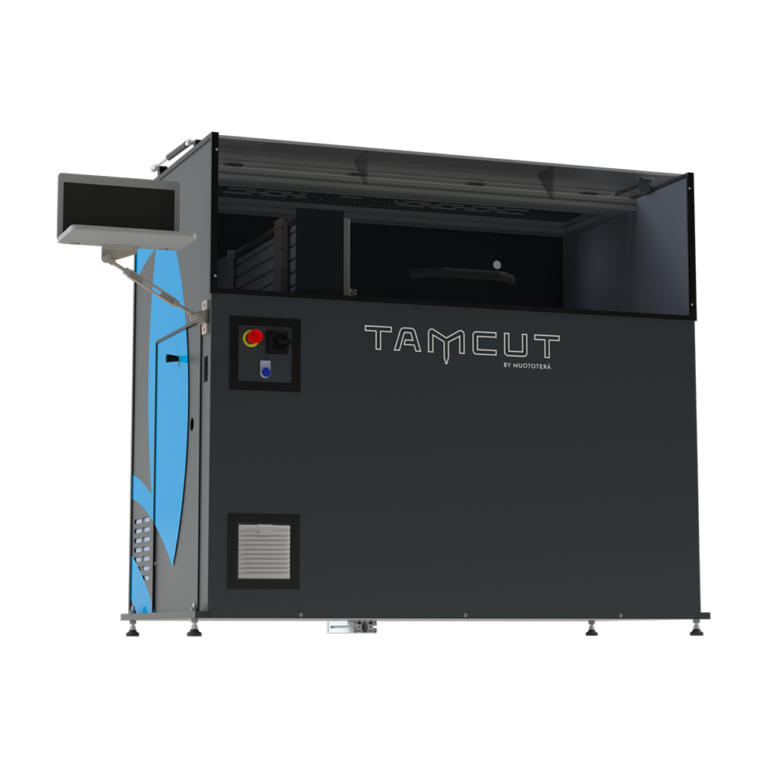

03

Cutting Head & Nozzle

The pressurized water (with or without abrasive) travels to the cutting head. Here, it’s channelled through a precision nozzle, which focuses the water into a narrow stream. This high-velocity jet is what performs the actual cutting, and its size and shape can be changed by using different nozzle types.

04

Control System

The TamCut is controlled by a laptop with all the necessary software pre-installed. The control includes a post processor for reading DXF and BMP files. In addition, an extensive material database is included, which helps to choose the right cutting parameters to achieve an optimal result. The cutting process can be simulated and cutting parameters can be adjusted while cutting.

05

Waste Management

Post cutting, the water used is typically drained away. TamCut has a basic filtration system to remove larger particles and abrasives, ensuring that the water disposed of is cleaner and reduces potential blockages.

06

Safety Measures

As in all machinery, safety is paramount with the TamCut. The machine features a closed cutting area, equipped with an opening lid. This design ensures that operators cannot encounter the high-velocity water jet during operation, providing an added layer of safety and protection. It also prevents splashes and reduces noise. The ability to access the cutting area only when it’s safe ensures that the risk of accidents is significantly minimized.

Muototerä - The Nordic waterjet company

We have clients in all industries and in all size classes all over the world. There is no typical client. Some have annual sales less than one million euro; others exceed 15 billion. Sometimes the CEO is operating the machine with couple of colleagues, other clients count their employees in thousands. We have this and everything in between. The only common nominator is the need to cut something with the most optimal way